CNC Stone- Granite CNC Cutting

CNC-30150M- Description

- Product Details

Features

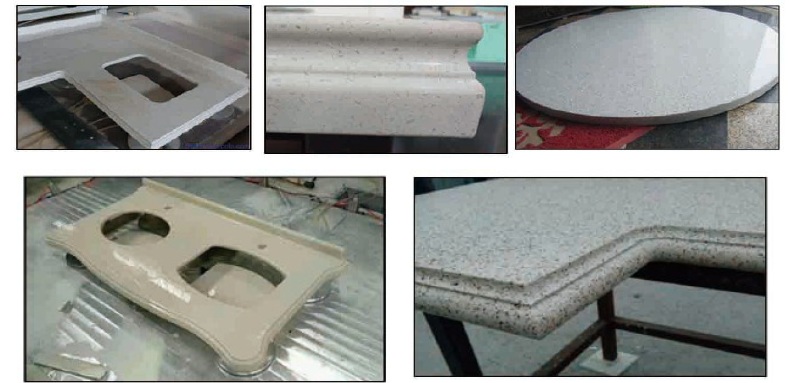

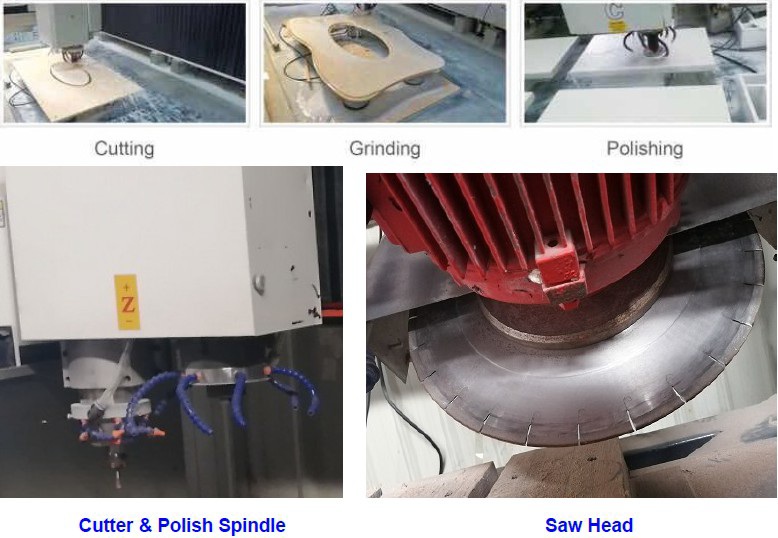

❖ Special design: Cutting, Profile Grinding & Polish process for Stone / Granite/ Quartz products.

❖ All “servo motor” driving system: All axes are driven by brush-less type, high torque AC servo motors.

❖ DSP CNC controller is set up to accept standard G-code programming formats along with on board conversational applications.

❖ An optional CAD/CAM system can create and edit programs then be sent to machine for easy cutting. DXF files can be imported, modified and edited from here to create a G-code.

❖ DNC is no longer required as the PC directly stores all part programs in a text editable file.

❖ Machine designed ready for 3-D cutting usage and superior performance.

❖ Moving gantry construction for space saving.

❖ The rigid steel frame construction has been stressed relieved prior to finish machining to provide repeatability and accuracy.

❖ Automatic frequency brake for the spindle allows rapid deceleration resulting in faster tool changes.

❖ Linear guides and sliding blocks are per-loaded with re-circulation bearings to ensure maximum rapid traverse and precision.

❖ The X & Y axis are equipped with a precision rack & pinion driving system. The Z axis utilizes a ball screw assembly complete with the per-loaded and ground screw for long life and optimum accuracy.

|

Model |

CNC-3015-M |

|

Working size |

3,000 × 1,500 × 400mm |

|

X Axis Travel |

3,000 mm |

|

Y Axis Travel |

1,500 mm |

|

Z Axis Travel |

450 mm |

|

Router Spindle |

Water Cooling 5.5 KW |

|

Router Spindle speed |

0 ~ 8,000 rpm |

|

Polish Spindle |

5 KW |

|

Processing System |

Custom Control System |

|

Servo Driver |

Euro servo motor |

|

Table |

Hard PVC Stainless water bank |

|

Rail |

30 mm Linear Rail |

|

Command |

G-Code、HP-GL |

|

Table |

Vacuum Osculum |

|

Control Box |

Independent |

|

Cooling System |

Water Cooling |

|

Water Tank |

Stainless Steel, Waterproof |

****** Custom Size available *****