ARES-5AX 5 Axes CNC Door Processing Machine Center

ARES-5AX 5 Axes- Description

- Product Details

ARES- 5AX Description

Distinctive Design for Door Pre-Hang Processing

- Automatic Feed Through (Options with Auto Loading and Out-Feeding)

- All the 5-side Project Processing

Top / Up Face: Door Lite Cutout, Cylindrical Lock / Dead Bolt Prep., Mortise Lock Face Prep. Hinge & lock edge: 3 Degrees

bevels, Lock / Dead Bolt Prep (Cylindrical), Mortise Lock, Latch Face Milling, Latch / Lock Bore Drilling, Flush Butt / Mortise

Hidden Hinges Face Milling, Screw Hole Drilling, Ball / Roller Catch, Weather Strip.

Top Castaly’s Woodworking CNC Machine are perfect for:

❖ Three-dimensional wood processing

❖ Cupboard doors

❖ Wooden doors

❖ Window processing

❖ Video game cabinets

❖ Door Lite Cutting

❖ Steel Door processing

Features

❖ DSP CNC controller is set up to accept standard G-code programming formats along with on board conversational applications.

❖ An optional CAD/CAM system can create and edit programs then be sent to machine for easy cutting. DXF files can be imported, modified, and edited from here to create G-code.

❖ Horizontal and vertical spindle for top and side stock processing

❖ Machine designed ready for 3-D cutting usage and superior performance.

❖ Moving gantry construction for space saving.

❖ The rigid steel frame construction has been stressed relieved prior to finish machining to provide repeatability and accuracy.

❖ Automatic frequency brake for the spindle allows rapid deceleration resulting in faster tool changes.

❖ Linear guides and sliding blocks are prismatic pre-loaded with recirculation bearings to ensure maximum rapid traverse and precision.

❖ The X & Y axis is equipped with a precision rack & pinion driving system. The Z axis utilizes a ball screw assembly complete with the pre-loaded and ground screw for long life and optimum accuracy.

ARES- 5AX Product Details

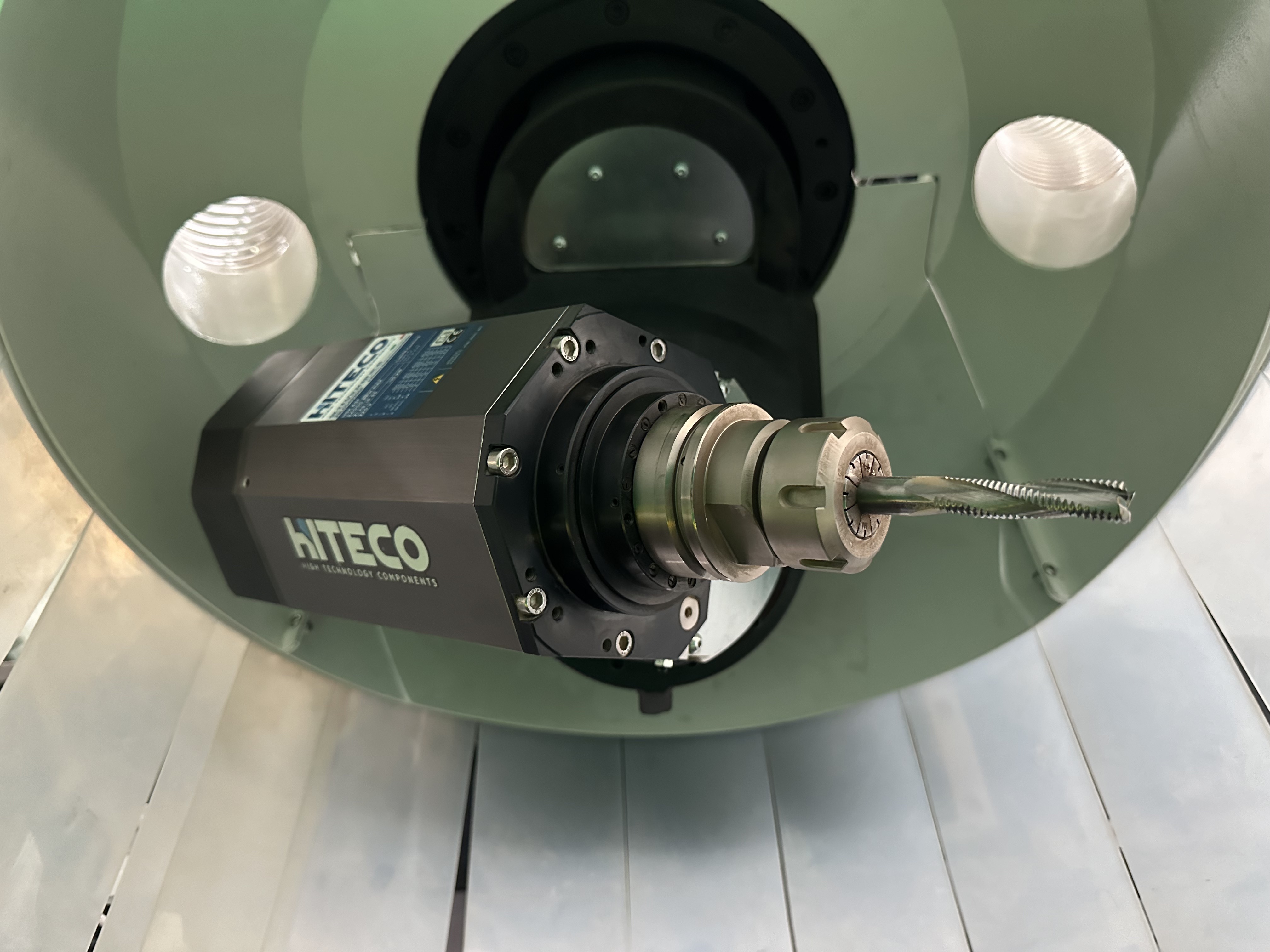

Hiteco 10 kw, 5 Axis A axis ±185 degrees, C axis ±320 degrees air cooling spindle with HSK-F63 tools.

Rotary Disc type 12 tools ATC

General Spec

1. Machine Gantry X Axis square rails Parallel vertical accuracy 0.001” (0.02mm)

2. Y Axis square rails Parallel vertical accuracy 0.001” (0.02mm)

3. Z Axis ball screw Parallel vertical accuracy 0.001” (0.02m)

4. Machine Re-position accuracy 0.001” (0.02mm)

5. Machine working accuracy 0.002” (0.5mm)

6. Grating ruler travel accuracy 0.002” (0.05mm)

Specification

※ Working size 51” (1300 mm) Width x 98” (3000 mm) Length x 11-7/8” (300 mm) Height (Mortise lock depth Maximum 5-1/2”)

※ Custom made door vacuum table (Optional Vacuum Pump)

※ Syntec 60WA control with All-in-one PC Controller

※ 1500w servo

※ Max travel speed 200 fpm (60m/min), Max working speed 50 fpm (15m/min) (According different processing material)

※ Professional PTP table with German SCHMALZ Vacuum pads 6pcs

※ 2M helical rack, CSK 35 Heavy duty square linear rails & Ball screw

※ Automatic control with Aluminum oil pipe Oil lubrication