Outlaw CNC Jamb & Louver 3 axis-Machining Center

Outlaw CNC Jamb & Louver 3 axis-Machining Center- Description

- Product Details

Outlaw Description

Technical details for the CNC Jamb& Louver machine:

Part Dimensions for Jamb:

Max Length-120", Max Width-14", Max Height-6"

Machines use fixed pins stop system at a specified z=0 stop and use lift bars to raise the jamb into position against this stop

Operations to perform:

Machine hinge pocket/dado on jambs

Part Dimensions for Shutters / Louver Rail:

Max Length-120", Max Width-1-3/4", Max Height-6"

Operations to perform:

Machine slots on angle-variable pitch

Clamping System Specification:

❖ Machines use fixed pins stop system at a specified z=0 stop and use lift bars to raise the jamb into position against this stop

❖ 7 upper fixed blocks use 14 guide rails to move up and down, and 7 side pushing cylinders

Controller Specification:

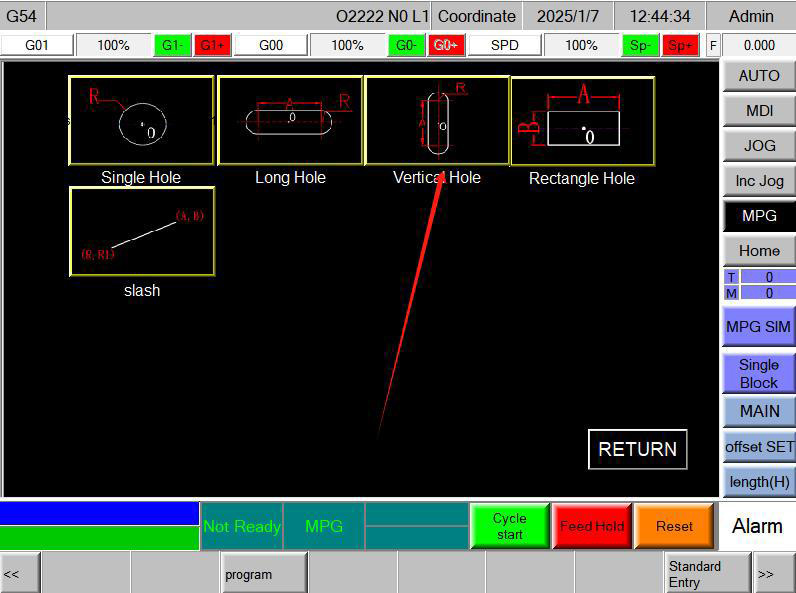

※Mfg Syntec #60WA control with All-in-one Industrial PC

※1500w servo motors and drives

※Max travel speed 200 fpm (60m/min), Max working speed 50 fpm (15m/min) (According different processing material)

※2M helical rack, CSK 35 Heavy duty square linear rails& Ball screw

※Automatic control with Aluminum oil pipe & lubrication

Outlaw Product Details

Electro Spindle Specification:

※4 Working Station

(1) Qty (1) 9 kW Quick Change ISO-30 Electro Spindle-Air Cooled

(2) Qty (1) 6 kW Collet Style Electro Spindle-Air Cooled

(3) Qty (1) 2.2kW Collet Style Electro Spindle-Air Cooled (Drilling Unit)

(4) Qty (1) 4 Way Chisel Unit-z axis servo control via Syntec Control

Machine Build/Tolerance General Specifications:

❖ Machine Gantry X Axis square rails Parallel vertical accuracy 0.001” (0.02mm)

❖ Y Axis square rails Parallel vertical accuracy 0.001” (0.02mm)

❖ Z Axis ball screw Parallel vertical accuracy 0.001” (0.02m)

❖ Machine Re-position accuracy 0.001” (0.02mm)

❖ Machine working accuracy 0.002” (0.5mm)

❖ Grating ruler travel accuracy 0.002” (0.05mm)

❖ 2M helical rack, CSK 35 Heavy duty square linear rails & Ball screw

❖ Automatic Guide/Ball Nut Oil Lubrication via PLC

❖ Moving Gantry construction for minimal footprint-(space saving)

❖ The rigid steel frame construction has been stressed relieved prior to finish machining to provide repeatability and accuracy.

❖ Automatic frequency brake for the spindle allows rapid deceleration resulting in faster tool changes.

❖ Linear guides and sliding blocks are prismatic pre-loaded with recirculation bearings to ensure maximum rapid traverse and precision.

❖ The X & Y axis is equipped with a precision rack & pinion driving system. The Z axis utilizes a ball screw assembly complete with the pre-loaded and ground screw for long life and optimum accuracy.